2012 Class Schedule

There are a few good spots left - come join us!

Register by email or call. Please read the registration information on the registration page.

![]() Gift Certificates Available! Click Here to Print

Gift Certificates Available! Click Here to Print

Turning and Tuning with Peter Galbert New! FULL

March 26-30

Cost $795

Materials - $100 - see participant information

Skill level- all

This class will be 5 lively days of exploring the craft of spindle turning to make parts for Windsor chairs. We'll start with basic turning skills and then tackle the elements and skills necessary to turn the more elaborate historical details. If you choose to enroll in the chair making class immediately following this turning class, you will be able to produce the turnings needed for your chair.

In addition to the turning component, we will take breaks from the lathe to learn to fine tune your chairmaking tools to raise your chairmaking skills to the next level.

About the Instructor

About the Instructor

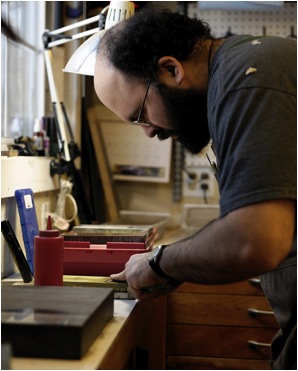

Before specializing in chairs, Peter Galbert worked as a cabinet and furniture maker in New York City. In 2001, he moved to Bethel, NY to make chairs from trees. Besides building chairs, he also teaches individual classes in chairmaking at his workshop in Upstate New York and larger classes at woodworking schools around the country. He also invented and produces the Galbert Caliper, a direct measuring tool for the lathe, and writes the Chair Notes blog (www.chairnotes.blogspot.com). Besides woodworking, Pete raises goats and chicken and makes maple syrup for his friends. His website is www.petergalbertchairmaker.com

Registration Information | Participant Information | Past class photos | Top of Page

![]()

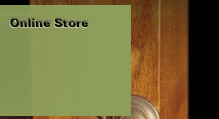

Sack Back Arm Chair with Peter Galbert New! FULL

Please choose to waitlist OR make a second choice...

April 1-7

Cost $975

Materials - $165 - see participant information

Skill level - all

The Windsor chair is an icon of American furniture. The sack back is one of the oldest and most successful of the Windsor designs. In this class we'll demystify the angles and curves that go into making a successful chair while demonstrating how hand tools are the most effective way to build an heirloom chair.

This 7 day class covers all the action from tree to chair while building a sack back armchair. You will split parts from a log, shave them, bend them and join them into their hand carved seats. We will cover topics including sharpening, wood technology, and design that will enhance your ability to go forth and make chairs at home. The legs will be provided for you, or you may turn your own chair legs before arrival at the class with instructor- provided patterns. Be ready to work hard and to learn a whole new way of woodworking.

Registration Information| Participant Information | Class Photos | Top of Page

![]()

Panel, Sash & Hinge: Traditional Joinery with Roy Underhill New!

April 13-15

Cost $550

Materials included

Skill level - all

Panel and Frame by Hand Method - As Joseph Moxon said, "Dovetail - Schmuvtail! It's panel and frame where you earn your biscuits!" Starting with laying out the guide sticks, you will move through cutting haunched and scribed mortise and tenon joints, plowing the grooves and fitting and raising the panels. You will make a single or double panel door or lid with either butted or molded and scribed shoulders for cabinets or cabins. So tallow up your plow plane and learn how to make your own darn doors!

Glazed Sash Work by Hand Method - No more window shopping - now you can make your own! Exacting, precise, and systematic - but window work is something that even Roy Underhill can muster! You'll learn the system for making both cabinet and architectural windows and take away a four-light ovalo-molded sash. We'll cover both British and American techniques including the sticking board and stick and rabbet plane. No pane - no gain!

Make the Roubo Bookstand - Make the one piece bookstand from Andre Roubo's "Art of the Joiner" and show that it can be done! After chiseling the round knuckles we'll rip open the "beau bois de noyer" and watch our bookstands unfold. We'll follow the French master's instructions and study more of his influential designs that so inspired Thomas Jefferson. As TJ said "I can not live without books" (but it's a good stand for your iPad as well).

About the Instructor

About the Instructor

Roy Underhill and has been teaching hand tool woodworking for over 35 years. As the host of the PBS series The Woodwright's Shop and as master housewright at Colonial Willliamsburg. He has helped millions of folks reconnect with the joy of handwork in wood. However, he does cut himself quite often, and over the years he has completely worn out the 32 known woodworking jokes. In spite of this, his newest book is pretty good.

Registration Information | Participant Information | Past class photos | Top of Page

![]()

Woodcarving Basics with Mary May New!

April 20-22 FULL

Please choose to waitlist OR make a second choice...

Cost $475

Materials included

Skill level - all

In this class you will practice the basics of woodcarving using traditional techniques that have been used for centuries. We will start with the process of getting the gouges razor sharp, then go over the basics of working with the grain, safely holding the gouges, and on to techniques of clamping down wood. The projects will start with a floral decoration carved in relief, then move on to a more traditional carving of a fan, and if time allows, a scalloped shell. You will encounter a variety of other tricks and techniques such as linen fold, bead molding & letter carving. This is a beginner class, but feel free to join us if you have some carving experience. The small size of the class will allow flexibility if you want to work on other projects.

About the Instructor

About the Instructor

Mary May is a European trained professional woodcarver with 20 years of experience in carving a variety of decorative details including sculpture, decorative fireplace surrounds, architectural details and period reproduction furniture. Mary has a workshop in her home in Charleston, SC, and offers classes in her studio as well as a variety of other locations. She is an active member of the Society of American Period Furniture Makers and teaches carving workshops at several of their locations. Mary was recently a guest on The Woodwright's Show with Roy Underhill and also teaches at his school in Pittsboro, NC. Mary's passion is to be able to share her knowledge of this art to anyone who has the desire to learn. www.marymaycarving.com

Registration Information | Participant Information | Past class photos | Top of Page

![]()

Cabinet Curiosities with Garrett Hack - FULL

Please choose to waitlist OR make a second choice...

April 30 - May 4

Cost $825

Materials - see participant information

Skill level - intermediate

Case construction is a fundamental furnituremaking skill. Designing and building a small cabinet is an ideal way for you to explore some fundamentals such as: strong case joinery, choosing appropriate materials, working with solid wood and wood movement, case backs, corner details, making and attaching moldings, and edge profiles of the top. These cabinets can have doors, shelves, and drawers (if we have time) so you will look at these important elements as well. Emphasis will be on hand skills and hand tools to size, smooth, shape, and fit parts. you will also learn to integrate machines to explore how to make the building process efficient and accurate.

About the Instructor

Garrett Hack is a furniture maker, author, and woodworking teacher from Thetford Center, VT, where he also runs a small homestead farm. He originally trained at Boston University's program in artistry and holds a degree in architecture from Princeton University. Internationally known, his work and Federal-inspired brick shop have been featured in numerous magazines and books, including "Architectural Digest," "The New York Times," and "Preservation" magazine. He is a contributing editor at "Fine Woodworking" and has written two books, The Handplane Book and Classic Hand Tools. Garrett spends about a quarter of his time teaching throughout the U.S., England, and Canada, and is former chairman of the Furniture Masters of New Hampshire. Visit Garrett's website Garrett Hack.com

Registration Information | Participant Information | Past class photos | Top of Page

![]()

Working with Curves with Garrett Hack New!

May 5-6

Cost $375

Materials included

Skill level - all

Welcome to a class where you will explore many aspects of producing and integrating curved elements into your work. The goal is to look at some of the practical challenges of curves - and there are many - while demonstrating numerous accessible ways that you can make curved parts. About half the class will be discussion, half hands-on.

You will explore one process for making strong and light curved pieces by laminating or gluing together thin layers over a form. We start with a drawing, make patterns if need be, build a form, resaw the laminations, glue them all together, and the next day true up the completed lamination in preparation for some joinery. This is where your work could start.

From here there are many options: You could opt to simply shape some curved solid wood parts such as a bowed drawer face or chair leg. Or, we can cut up the lamination and each take a part to work with in some way. It could be treated as part of a curved drawer face with a drawer side dovetailed to it. Or it could be a curved rail mortise and tenoned to a leg. There are plenty of other possibilities! What you choose to try depends on how you might want to use curves in your work.

In addition to lamination, we will discuss and demonstrate many more aspects of making and working with curves. While there is no question that creating curves is more challenging than squares and rectangles, you will find that incorporating curves into your pieces is worth the extra effort.

Registration Information | Participant Information | Past class photos | Top of Page

![]()

Introduction to Traditional Handtools with Ron Herman New!

May 21-26

Cost $825

Materials included

Skill Level - Intermediate

The two-generational gap between the old masters and young apprentices has created a lack of knowledge about proper use of hand tools. So catch up and jump in to this class for a deeper look at working with cabinet-maker and carpenter tools.

Each day we will take a new group of tools, identify uses for them, tune them, adjust them, and  learn how to use them properly.

learn how to use them properly.

You will learn to identify wood microscopically, giving you a better understanding of how to apply a tool to a specific species of wood. You will learn to identify, tune and use metal, transitional and wood-body planes, handsaws and a variety of every tool found in the tool chest. If you wish, bring your own tool-chest in order to learn about the tools you already own, especially hand planes, handsaws and chisels.

About the Instructor

Ron Herman is the third-generation owner of Antiquity Builders of Ohio, a century-old family business. As a master housewright and carpenter, Ron works on historically accurate restoration projects and has worked with traditional handtools for over 30 years!

Registration Information | Participant Information | Past class photos | Top of Page

![]()

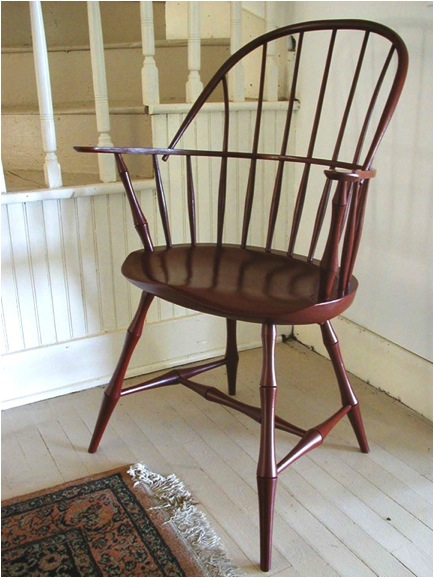

Making Wooden Molding Planes with Larry Williams & Don McConnell

June 4-8 - FULL

Cost $825

Materials $50

Skill level - all

If you are like many woodworkers, you may find that there are few more gratifying experiences than producing your own tools. In this class using hand tools and traditional techniques, you will make a pair of #8 hollow and round planes that share the features and function of those made by the best plane makers of the past.

We'll explore the history of molding planes and their evolution. While molding planes appear simple they're highly evolved; often with subtle features that make a difference in their use. The planes you create will incorporate important details that enable greater utility and agility.

There are many easily learned skills involved in this class that also transfer to other aspects of woodworking. You will learn dependable and repeatable sharpening techniques that apply to profiled tools like those used in carving and to more common straight edged tools like bench chisels and bench planes. You will also learn to easily and accurately heat treat tool steel for the planes produced in this project and for future needs.

You'll gain experience with tools you may not have used before. Floats will enable you to work deep into places you can barely see into and to do it accurately. Gimlet bits will allow you to "steer" hand-bored holes exactly where you want and need them.

We'll end by surveying some basic techniques of using hollow & round planes to produce classic molding profiles. You'll be able to experiment with creating a few traditional moldings with your new planes and to try out a few dedicated molding planes as well.

You'll leave this class enabled by new skills, fresh knowledge, confidence and a pair of hollow and round planes you'll be able to use to enhance your future work.

About the Instructors

About the Instructors

Larry

In 2006 Larry Williams was honored with the "Living Treasure" award from the Arkansas department of Cultural Heritage for his efforts in reviving the traditional craft of making wooden planes. Lie-Nielsen recently released Larry's DVD on plane making. Larry worked in architectural woodworking for 25 years and began experimenting with plane making in the late 1970's. His work and articles have been featured in a number of woodworking books and magazines. Larry was a founding partner in Clark & Williams now reorganized into Old Street Tool, Inc. The company continues to produce traditional Western-style wooden planes.

Don

Don McConnell made his first wooden planes in the late-1970's while building furniture in the cabinet shop of the Ohio Village. He continued his plane making activities over subsequent years while building custom furniture in traditional styles and undertaking one-of-a-kind architectural woodwork including carved elements of geometric handrails. His work has been featured in several magazines and exhibits. A former contributing editor for Popular Woodworking magazine, Don is also co-author of Hand-Saw Makers of Britain. He is a co-owner of Old Street Tool, Inc. More than 300 of the firm's planes are currently in use in the conservation and Historic Trades departments at Colonial Williamsburg.

Visit their website at www.planemaker.com

Registration Information | Participant Information | Past class photos | Top of Page

![]()

Using Traditional Molding Planes with Don McConnell

June 9-10

Cost $345

Materials $19

Skill level - all

Learn how you can enrich your furniture projects, with complete freedom, through the use of Hollows & Rounds, and a few associated hand planes. Begin by gaining a familiarity with the "vocabulary" of classical moldings, their characteristics, uses, and designs. Learn to design your own classical moldings which are informed by proportions and principles found in the classical orders, and with an eye toward the tools used to create them. This learning will be re-enforced by hands-on experience designing, laying out, and executing some classical moldings. Along the way, we'll discuss the selection, tuning, sharpening and use of a variety of molding planes - skills and knowledge which you can take home to your own shop.

Finally, you will explore ways in which classical techniques and tools can be used to enhance more contemporary furniture projects to your personal taste. The emphasis will be on learning to add visual and tactile interest, while manipulating the visual weight and relationships of various elements of your projects. Enabled by this skill and knowledge, the "profiles" of your projects need be limited only by your imagination.

Registration Information | Participant Information | Past class photos | Top of Page

![]()

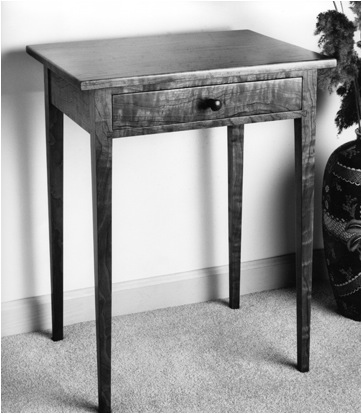

Build a Classic Side Table with Kelly Mehler

June 18-22 FULL Please choose to waitlist OR make a second choice...

Cost $895

Materials included

Skill level - all

In this foundational class you will build a small cherry or walnut side table. The side table has proven to be a popular project for both new and experienced woodworking enthusiasts. The side table class focuses on important skills that include basic joinery, drawers, gluing, machine and hand tools use - all valuable skills used in nearly all woodworking projects. The piece that you create is adaptable to a variety of uses and can fit into many kinds of home or office decors.

The highlights of this class are:

• Tuning, sharpening and using hand tools

• Matching wood for a pleasing unified appearance

• Efficient machine tool milling

• Safe use of power and hand tools

• Mortise and tenon joinery

• Hand cutting dovetails

• Making and fitting a dovetailed drawer

• Gluing and assembly

Daily demos followed by practice will give you step-by-step instruction and tips for successfully completing your side table.

As in all our small classes, you will work at your own pace and will receive lots of individual attention.

Registration Information | Participant Information | Past Class Photos | Top of Page

![]()

Mortise and Tenon Joints by Hand with Jeff Miller New!

July 14-15 FULL Please choose to waitlist OR make a second choice...

Cost $365

Materials Included

Skill level - all

Maybe you shy away from hand cut mortise and tenon joinery. Maybe you think it is too difficult, or too slow, or too sloppy! In this class you will practice the basic skills needed to master this essential joint. You will move from the basics through complex applications, including angled (and compound-angled) joints and mortise and tenons on pieces with curves. Though these joints may seem intimidating, these skills are not difficult to learn and will improve your work in any project or application.

In addition to learning the basic skills for hand-chopping mortises and sawing tenons, we'll cover precise fitting of all of these joints, and the strategies and tools that help make that possible. You'll also build some simple jigs that will enable you to make mortises and tenons quickly and accurately, with repeatable, reliable results.

Registration Information | Participant Information | Past Class Photos | Top of Page

![]()

Chair Design with Jeff Miller New!

July 16-21 2 spaces available

Cost $895

Materials $60 - see participant information

Skill level - all

There are three basic ways to approach the design a chair; each one focusing on one of the three most significant elements of a good chair design. You can start with either the comfort, the structure, or the visual aspects. I find that starting with comfort leads more reliably to a useable chair, and often adds to the visual appeal of the chair as well, since comfortable curves tend to be ones that are quite interesting visually.

This will be a chair design class where we start off with an exploration of what makes a chair comfortable. Then we will build a variety of comfort prototypes and discuss ways of testing out ideas for comfort. From your prototype, you will design your own chair. In the process of working out the overall design of the chair from the comfort prototype, we will cover significant issues of structural integrity and successful visual appeal as well. We'll experiment with different methods for examining and refining the evolving design. The ultimate goal of the class is for you to put together a functioning prototype of your chair design, utilizing a number of different 'short-cut' joinery techniques.

About the Instructor

About the Instructor

Jeff Miller turned to designing and making furniture after a career as a classical musician. His furniture has been in shows around the country, has won numerous awards, and is in the collection of the Chicago History Museum. His book, Chairmaking and Design (Linden Publishing) won the Stanley Award for Best How-To Book of 1997 (and his companion video Chairmaking Techniques won best video as well). He has also written the books, Beds, and Children's Furniture and has contributed chapters to Furniture for All Around the House, and Storage Projects for All Around the House, all for The Taunton Press. His newest book, on craftsmanship, will be released in the fall of 2012. Jeff is a frequent contributor to Fine Woodworking and now Popular Woodworking magazines. He is an active teacher at furniture schools around the country.

Visit Jeff's website at Furniture Making.com

Registration Information | Participant Information | Past class photos | Top of Page

![]()

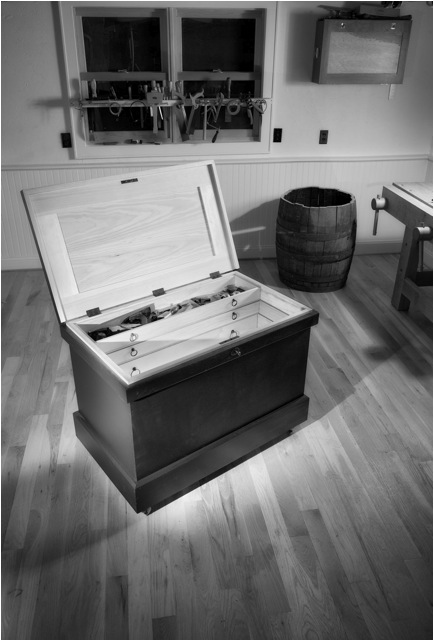

Build an 18th-century Tool Chest with Christopher Schwarz New! FULL

Please waitlist OR Make second choice

July 30 - Aug 3

Cost $795

Materials $425/$375 see Participant Information

Skill level - all

Aside from a workbench, a sturdy tool chest is one of the most important things to have in your shop. It organizes and protects your tools from damage, rust and loss. While many woodworkers have attempted to improve upon the traditional chest design that emerged 300 years ago, the old form has remained the absolute best way to keep the most amount of tools in the smallest space.

In this five-day class you will build the shell of your own traditional tool chest using hand tools and techniques. This is an excellent first project for a new hand-tool woodworker. Skills you will learn in this class include:

• Truing up panels using bench planes

• Traditional through-dovetail joinery

• Cutting basic mouldings by hand

By the end of class you will have all the skills you need to complete the interior of the chest at your workshop at home, whether you want to make just a few sliding tills or even a full-blown interior cabinet with dovetailed drawers.

About the Instructor

About the Instructor

Christopher Schwarz is the editor of Lost Art Press, a publishing company that specializes in producing books and DVDs on hand woodworking. He was an editor at Popular Woodworking magazine for almost 15 years where he worked to rebalance the scales of media coverage of handwork and machine woodworking. He is now a contributing editor for Popular Woodworking and The Fine Tool Journal. Chris is the author of six books on handwork including "Workbenches: From Design & Theory to Construction & Use" and "The Anarchist's Tool Chest." He is a long-time woodworker - he built his first workbench when he was 11.

Visit Chris's Website at Lost Art Press

Registration Information | Participant Information | Past class photos | Top of Page

![]()

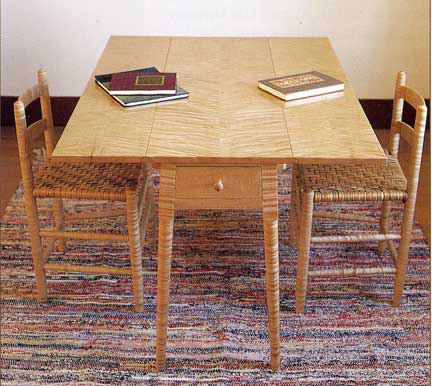

Build a Drop Leaf Table with Kelly Mehler

August 13-18

Cost $895 - FULL

Please waitlist or make a second choice

Materials - see participant information for details

Skill level - intermediate

Yes you can make this classically elegant drop leaf table!

The drop leaf table is popular because it occupies a rather small space when not in use, but seats a number of people when friends and family gather. The expanse of flat surfaces makes this a good project for showing off the beauty of your chosen wood.

In this 6 day hands-on class you will build a splayed leg drop leaf table through which you will learn such techniques as:

• Safe and correct machining practices

• Efficient and accurate mortise and tenon joinery

• Splayed leg and apron construction

• How to make and fit a classic rule joint

• Installing and fitting drop leaf hinges

• Adding drop leaf supports

• Building and fitting an optional dovetailed drawer

Get in on the action where rule joints RULE!

Registration Information | Participant Information | Past class photos | Top of Page

![]()

Hand-Cutting Dovetails - Weekend with Kelly Mehler

Hand-Cutting Dovetails - Weekend with Kelly Mehler

August 25-26

Cost $345 - includes materials

Skill Level - Open to all

Find out that this preeminent joint is well within your grasp! This beautiful, useful, and long lasting joint will be our focus for this two-day hands-on class. You will learn methods that may be difficult to read about, but which become very doable with hands-on instruction.

Here's what we'll do:

- Learn how to sharpen chisels.

- Lay out through dovetails and half blind dovetails.

- Learn methods for hand sawing and chiseling dovetails.

- Cut and fit through dovetails, half blind and mitered dovetails.

- View demonstrations and receive 1-on-1 instruction.

By the end of the weekend, your knowledge of tool sharpening will enhance your ability to create clean and beautiful dovetails and other joints needed for your projects. You will have a good foundation for successfully adding several types of hand-cut dovetails to your woodworking repertoire.

Registration Information | Participant Information | Past class photos | Top of Page

![]()

Build a Roubo Bench with Jameel Abraham, founder of Benchcrafted New! FULL Please choose to waitlist OR make a second choice...

Sept. 3-8

Cost $975

Materials $900

Skill level - intermediate

The popularity of Andre Roubo's French workbench has exploded over the past few years. Countless Roubo benches have been built in the mean time, and woodworkers are enjoying a return to this proven, fundamental bench design. Made of massive elements, the bench becomes a monolithic workholding monster that will easily handle any work you throw at it, from small projects to large case pieces. The Roubo design has become popular for a reason.

Jameel has built several Roubo benches over the past few years not only for private individuals, but also for professional woodworkers. However, this won't be a class for those looking to learn about which is the best type of bench, or why one vise is better than another (more on this later). This class will be all about building an ancient, proven design quickly and efficiently, so you can take it back to your shop and start building furniture right away. What usually takes weeks or months of after-hours work for an individual, will be accomplished as a team in just a few (hard working) days. A massive bench like the Roubo is a motivating project, but its also hard work. Expect to get sweaty and tired every day. This class is physically demanding. You need to be a burly dock worker one minute, and a precision joiner the next. None of the work requires extreme skill, but you'll have to keep your wits about you and keep on task in order for the bench to turn out right at the end of the six days.

Jameel's bench design, the Split-Top Roubo (which the school built several of in 2010) will be the focus of the class. Although the bench features a two-piece benchtop and both Benchcrafted vises, it can easily be built with a single top or other vises depending on your budget and workholding requirements. Before the class Jameel will consult with each student regarding workholding, joinery options, bench height and overall size. We'll get the details down ahead of time so class time can focus entirely on construction.

About the Instructor

About the Instructor

Jameel Abraham grew up spending time in both of his grandfather's shops, who were both avid hobbyist woodworkers. After studying Russian language briefly in college he dropped out to pursue mural painting and woodcarving in the Byzantine style, and continues to work professionally in both areas today. He has also worked as a luthier, specializing in the oud, a Mediterranean string instrument that is the precursor of the the European lute and guitar. Lately his interests have moved to designing, improving and reproducing historical workholding devices and benches through Benchcrafted, a company he founded with his brother in 2006. His benches and vises have been featured in "The Workbench Design Book" by Christopher Schwarz. He has also written articles on bench joinery and inlay for Popular Woodworking Magazine.

Visit Jameel's website at Benchcrafted

Registration Information | Participant Information | Class photos | Top of Page

![]()

Furniture Design: Greene & Greene and Beyond with Darrell Peart New! 2 spaces available

September 15

Cost $175

Skill level - all

This class is intended as an introduction to furniture design from Darrell's particular perspective, which is heavily influenced by the Arts & Crafts Movement and by Greene & Greene. While much of the information will revolve around the designs of Greene & Greene - it will not be limited to such.

You will be asked to obtain William Varnum's book "Arts & Crafts Design" and read chapters two through four prior to attending the class. You are requested to bring a sketch (of your own design) to class as a jumping off point for conversation.

The class will start with some basic rules of design and a slides illustrating examples of basic proportioning and balance. While Darrell acknowledges rules of design as valid, he also believes the rules must ultimately be laid aside in favor of intuition. This class will offer some basic rules to get you started as well as strategies for breaking away and relying upon your own intuition.

For more on Darrell's design perspective see:

* Rules are for Fools (also published in the November 2009 issue of Popular Woodworking)

* (http://furnituremaker.com/rules_are_for_fools.htm)

* Woodwork Magazine (Winter 2010) Furniture DNA

* Design DNA (Darrell's Blog entry)

* http://darrellpeart.blogspot.com/2009/03/design-dna.html

About the Instructor

Darrell started his career in the early 1970's making and selling small wooden items at Seattle's Pike Place Market. To broaden his experience, he subsequently worked for many years in various high-end custom shops throughout the Puget Sound area, gaining an extensive background in both commercial and custom furniture making.

In 1989 he discovered the American Arts & Crafts Movement and in succession was captivated by the works of Charles and Henry Greene.

Although Greene & Greene is Darrell's primary inspiration, James Krenov, Thomas Chippendale, and Gothic furniture have also influenced him in one way or another.

Darrell teaches furniture making and design at various woodworking schools across the US.

He has written for Home Furniture, Today's Woodworker, Fine Woodworking, Woodwork ,Popular Woodworking, American Woodworker, and Style 1900 magazines. His first book, "Greene and Greene: Design Elements for the Workshop" was published in April 2006 by Linden Press. Darrell is currently working on his second book on Greene & Greene style furniture. His work has appeared in various galleries; has been featured in both local and national newspapers, magazines, and books; and in private collections throughout the US.

Visit Darrell online at www.furnituremaker.com

Registration Information | Participant Information | Past class photos | Top of Page

![]()

Arched Aurora End Table with Darrel Peart New! FULL

Please choose to waitlist OR make a second choice...

September 17-22

Cost $895

Materials - see participant information

Skill level - intermediate

Small tables are a great way for you to learn and explore new woodworking techniques and details. This small table is no exception to that rule. Your woodworking bag of tricks will be bulging with numerous new items, not the least of which will be several classic Greene & Greene design elements.

The design is an original by Darrell Peart and is heavily influenced by Greene & Greene, but embraces other influences as well. You can choose to make either a nightstand or an end table by simply changing the height dimension of the legs..jpg)

The six-day course will be filled with discussions (and related tangents as well) on three of Darrell's favorite subjects: woodworking, Greene & Greene, and furniture design.

Some of the Items covered will be:

* Greene & Greene Details

o G&G style bread board end

o Proud ebony spline

o Cloud lifts

o Ebony plugs

o Proud "pillowed" fingers

o Waterfall legs

* Krenov style "Block & Dowel Pull

* Fitting of an irregular shaped drawer

* Drawer construction

* Hanging drawers on wooden runners

* finger joints

Registration Information | Participant Information | Past class photos | Top of Page

![]()

Contact Kelly Mehler P.O. Box 786, Berea, KY 40403 phone (859) 986-5540 fax (859) 986-1233

email: kelly@kellymehler.com

© 2009 designed by Flying High Design.